Understanding Connected Load Vs Demand...

January 2, 2026

Load calculations are the backbone of HVAC design. They determine how much heating and cooling a building requires, which in turn guides equipment sizing, energy consumption, and occupant comfort. For decades, engineers have relied on different methods to perform these calculations; starting with manual tables and formulas, later transitioning to early computer tools, and now using dynamic simulation engines.

This evolution reflects not only advances in technology but also a broader shift in building design philosophy: from quick estimates for equipment sizing to sophisticated modeling that drives energy efficiency and sustainability.

Before the widespread use of computers, engineers carried out heating and cooling load calculations by hand using ASHRAE handbooks. Two of the most popular methods were:

These approaches simplified complex physics into tables that engineers could look up and apply directly. A designer in the 1970s might calculate a wall’s heat gain by selecting values from CLTD tables, applying correction factors, and summing up results across building components.

Advantages: Easy to use, simple to teach, standardized.

Limitations: Could not fully capture time-varying loads, solar radiation, or thermal mass effects.

The rise of personal computers in the 1980s and 1990s transformed load calculations. Software tools automated the same manual processes, improving speed and reducing human error.

Key milestones included:

These tools made it feasible to model large, complex projects quickly. However, they still relied on approximations rather than detailed physics-based simulations.

Advantages: Faster, more consistent, fewer manual errors.

Limitations: Still simplified, lacked full accuracy in dynamic building behavior.

As buildings became more complex, engineers needed more precise tools. Two major methods shaped modern practice:

Advantages: Physics-based, highly accurate, captures dynamic behavior.

Limitations: More computationally intensive, requires detailed input data.

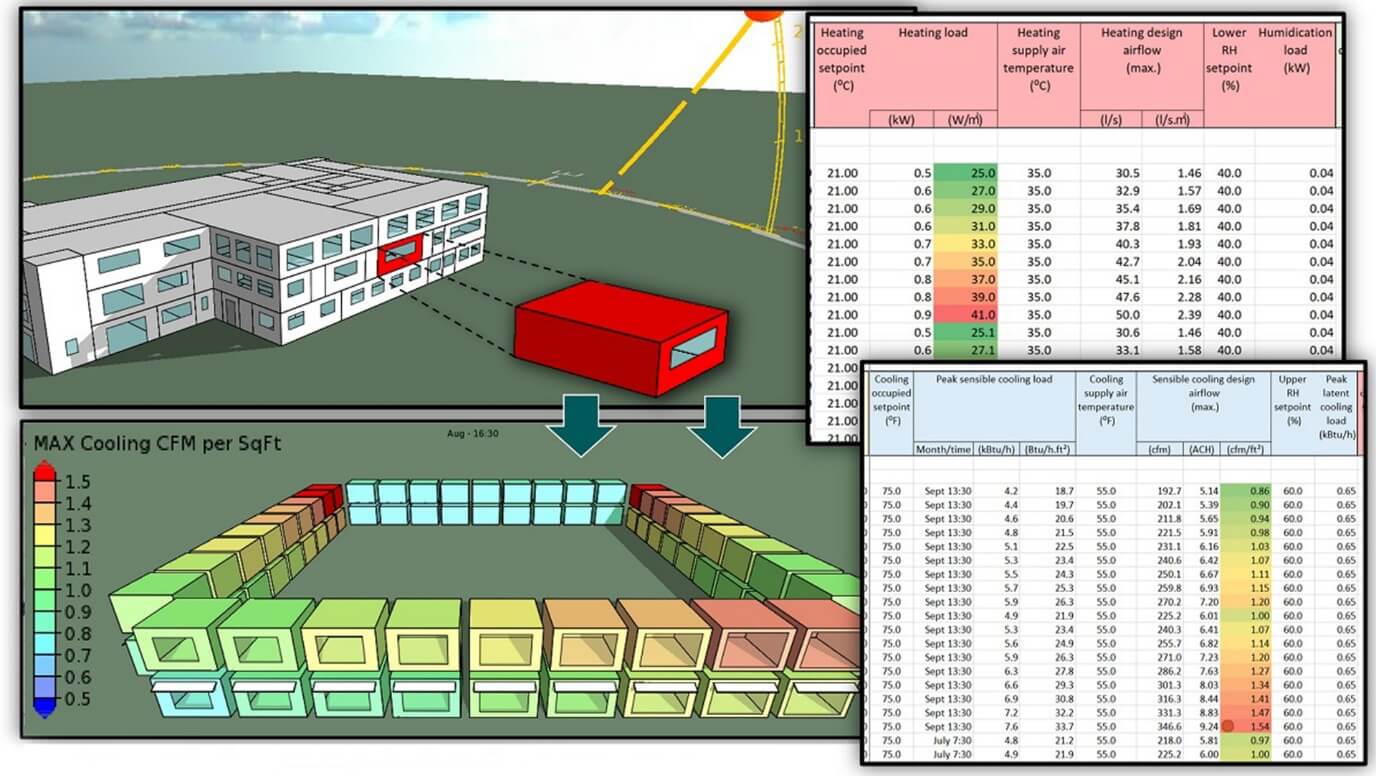

Modern HVAC design relies heavily on simulation. Load calculations now extend beyond equipment sizing to influence building geometry, materials, and overall energy strategy.

Current practice includes:

Emerging trends are pushing boundaries further:

Accurate load calculations translate directly into:

The industry is shifting from compliance-driven modeling (just meeting codes) toward performance-driven modeling (actively designing for sustainability and efficiency).

The evolution of HVAC load calculation methods from hand tables to dynamic simulation mirrors the growth of the industry itself. Early methods like CLTD and TETD provided the foundation, while modern techniques such as RTSM and HBM define today’s standard practice.

For today’s engineers, the challenge is not only to use these advanced tools but also to understand the fundamentals behind them. The core principle remains the same: accurate load calculations are central to sustainable, efficient, and comfortable building design.

From hand calculations to simulation, the journey illustrates how far HVAC design has progressed and how much potential remains ahead.