Understanding Connected Load Vs Demand...

January 2, 2026

In discussions about electrical system safety, two terms often come up: AIC (Ampere Interrupting Capacity) and SCCR (Short-Circuit Current Rating). While they both relate to handling fault currents, they serve different purposes and apply to different components of the electrical system. Despite sounding similar, it’s important to understand the distinction between them.

SCCR represents the maximum short-circuit current that an electrical assembly can safely withstand without suffering damage or posing a hazard. This rating is essential for equipment such as industrial control panels, machinery, and other assemblies. It ensures the entire system can survive a fault condition safely.

The National Electrical Code (NEC) and UL 508A require that equipment be clearly marked with its SCCR. This helps ensure that the system components are properly rated for the available fault current at their installation location, thereby maintaining safety and compliance.

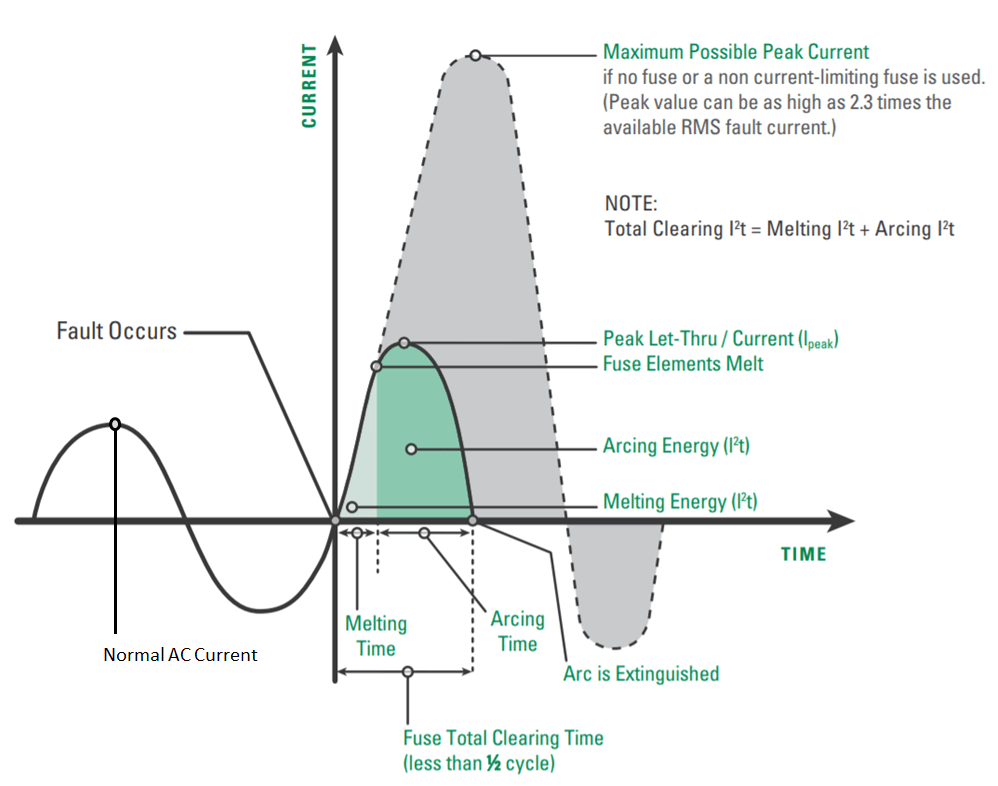

AIC (Ampere Interrupting Capacity) defines the highest level of fault current that a protective device, such as a fuse or circuit breaker, can interrupt safely without sustaining damage. This rating specifically applies to individual overcurrent protection devices, not entire systems.

| Ampere Interrupting Capacity (AIC) | Short-Circuit Current Rating (SCCR) |

|---|---|

| AIC applies specifically to individual overcurrent protection devices, such as fuses and circuit breakers. | SCCR applies to entire assemblies or panels, such as industrial control panels or switchboards. |

| The purpose of AIC is to verify that a protective device can safely interrupt high levels of fault current without malfunctioning or causing damage. | The purpose of SCCR is to confirm that an electrical assembly can safely withstand a short-circuit event without causing damage, fire, or posing a safety risk. |

| AIC is determined by testing the individual device per UL489 or UL:248 | SCCR is determined by evaluating the weakest link in the assembly, often via UL 508A |

Misunderstanding between AIC and SCCR is fairly common, especially among engineers, electricians, and system designers. This confusion stems from several key factors:

Before the 2005 revision of the National Electrical Code (NEC), industrial control panels were not required to display their Short-Circuit Current Rating (SCCR). As a result, many professionals were educated with an emphasis only on AIC, making SCCR seem like a recent or unnecessary addition to system design.

Both AIC and SCCR are expressed in kiloamperes (kA) and relate to short-circuit conditions, which contributes to the misunderstanding. The terms sound similar and are often listed together in electrical documentation, leading to the assumption that they are interchangeable.

While AIC refers to the interruption capacity of an individual device (e.g., a circuit breaker that can safely interrupt up to 22kA), SCCR applies to entire assemblies or systems, requiring an evaluation of how all components interact during a fault. This difference in scope is frequently overlooked.

The NEC uses terms like “short-circuit current rating” in ways that aren’t always clearly differentiated from AIC. This lack of clarity leads some designers to assume that an “interrupting rating” listed on a breaker also applies to the panel it is installed in.

However, UL 508A requires panels to be evaluated as a complete assembly, separate from individual device ratings.

Electrical systems must be designed not just for everyday performance but also for extreme fault conditions such as short circuits.

In such events, tens of thousands of amps can surge through a system within milliseconds, creating serious hazards. Potential consequences include:

To prevent such outcomes, both AIC and SCCR ratings are essential:

Understanding and correctly applying AIC and SCCR ratings is essential for:

To ensure compliance with AIC and SCCR requirements:

While both AIC and SCCR ratings are crucial for electrical system safety, they apply to different aspects: AIC pertains to the interrupting capacity of individual protective devices, whereas SCCR relates to the overall assembly’s ability to withstand fault currents. Proper understanding and application of these ratings are vital for preventing equipment damage, protecting personnel, and ensuring compliance with safety standards.