Understanding Connected Load Vs Demand...

January 2, 2026

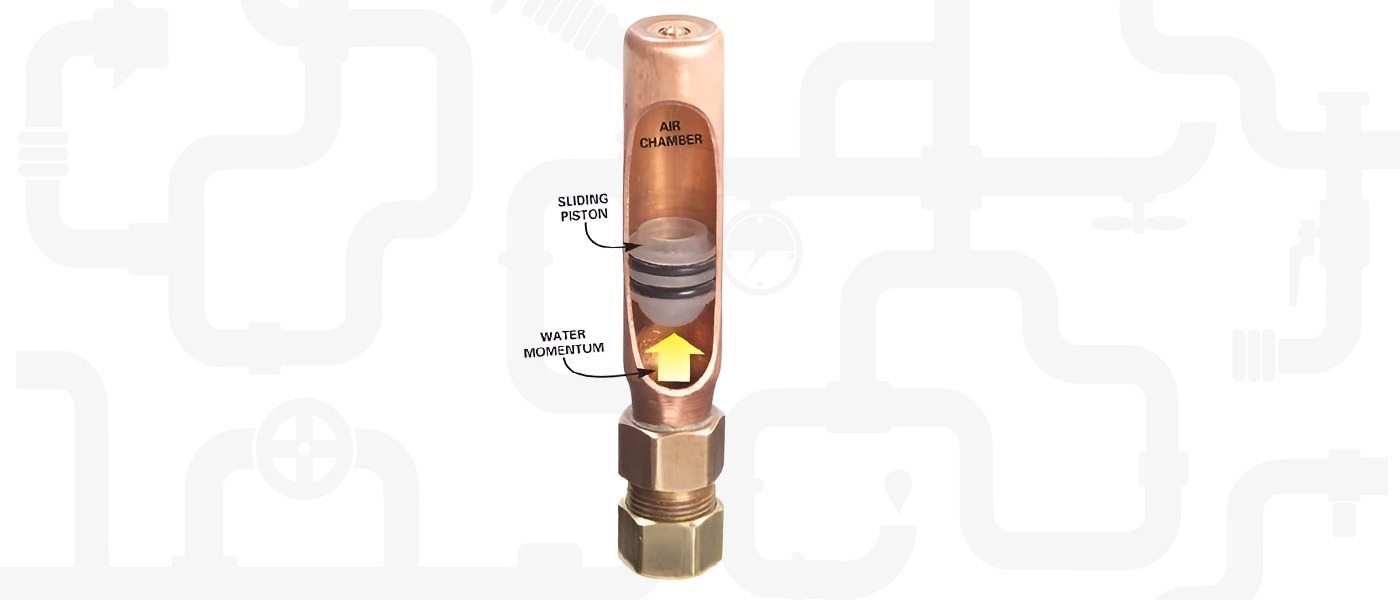

Water hammer is a common but often overlooked issue in plumbing systems that can lead to noise, pipe damage, and long-term infrastructure issues. The sudden stoppage of flowing water creates a pressure surge, producing a loud banging sound and potentially weakening the piping system over time. Water hammer arrestors (WHA) are critical components in mitigating this issue, protecting plumbing infrastructure, and ensuring system longevity.

This article explores the importance, function, placement, and latest advancements in WHA technology, while referencing key standards, including the Plumbing & Drainage Institute (PDI) WH- 201, ASME A112.26.1, UPC (Uniform Plumbing Code), and IPC (International Plumbing Code).

Water hammer occurs when a fast-closing valve suddenly stops water flow, creating a pressure shockwave in the piping system. This shockwave can exert excessive force on pipes, causing:

WHA devices are essential in preventing these issues by absorbing the excess energy and maintaining pressure stability.

This compression effect spreads the momentum over a longer period, reducing the peak force and preventing damage.

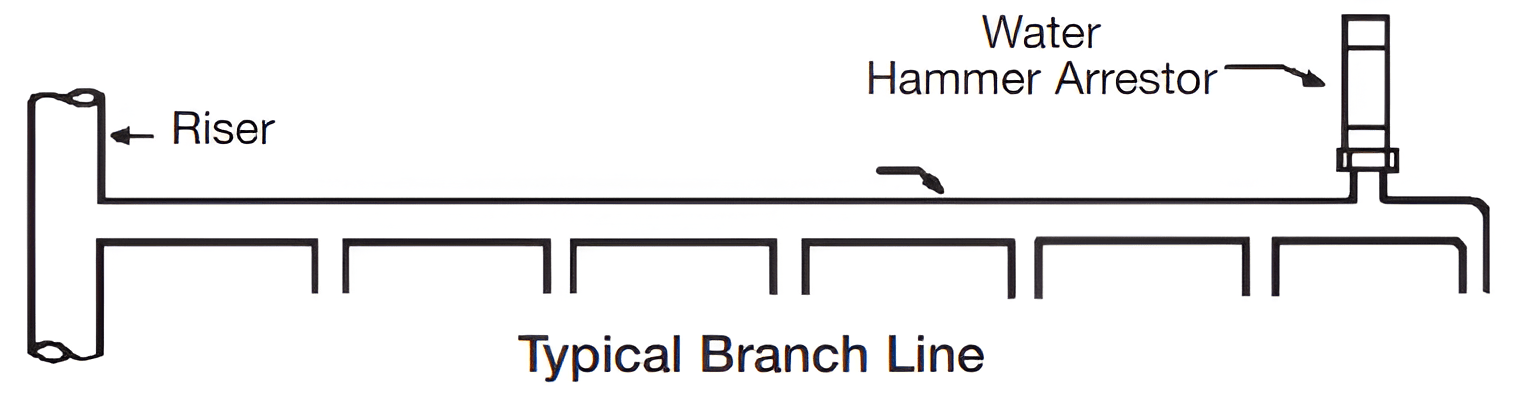

Water hammer arrestors function by providing a shock-absorbing mechanism within the plumbing system. They are installed at key locations where quick-closing valves exist, such as:

When the water stops suddenly, the air or piston inside the WHA compresses, absorbing the kinetic energy and eliminating the hammering effect.

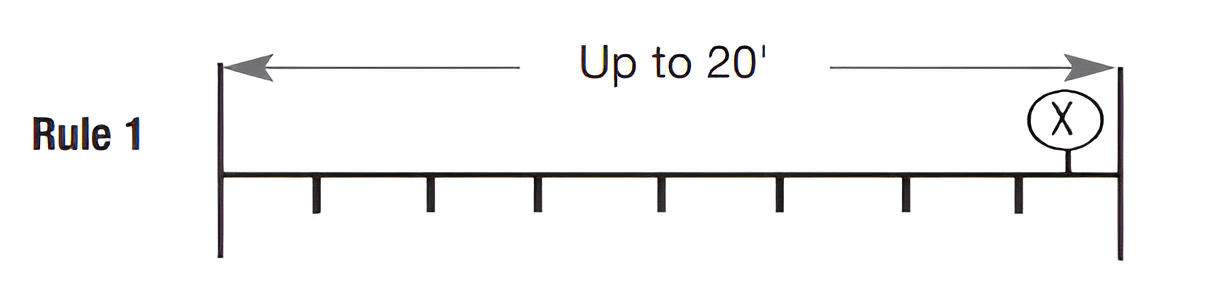

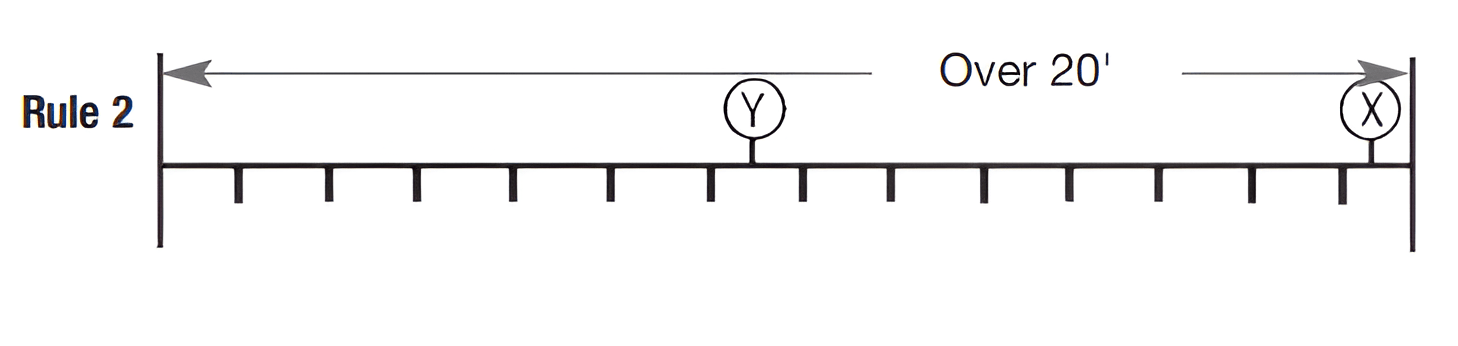

Proper placement of WHA devices is critical to their effectiveness. The PDI Standard WH-201 and ASME A112.26.1 provide clear guidelines on installation, stating:

Several international and U.S. plumbing codes regulate the installation and sizing of WHAs:

2. International Plumbing Code (IPC) – Section 604.9

3. ASME A112.26.1

4. Plumbing & Drainage Institute (PDI) WH-201

Modern WHA technology has evolved to offer more efficient and durable solutions:

These innovations improve longevity, ease of maintenance, and overall system efficiency.

Water hammer arrestors are indispensable components in modern plumbing, protecting pipes, fixtures, and appliances from sudden pressure surges. Their proper placement and sizing, guided by PDI WH-201, UPC, and IPC standards, ensure effective performance. With recent advancements, WHAs continue to evolve, offering smarter, more durable solutions to prevent costly plumbing damage.

For engineers, plumbers, and homeowners, investing in high-quality WHAs is a proactive step toward Enhancing System Longevity, Reducing Noise, and Ensuring Regulatory Compliance.