Understanding Connected Load Vs Demand...

January 2, 2026

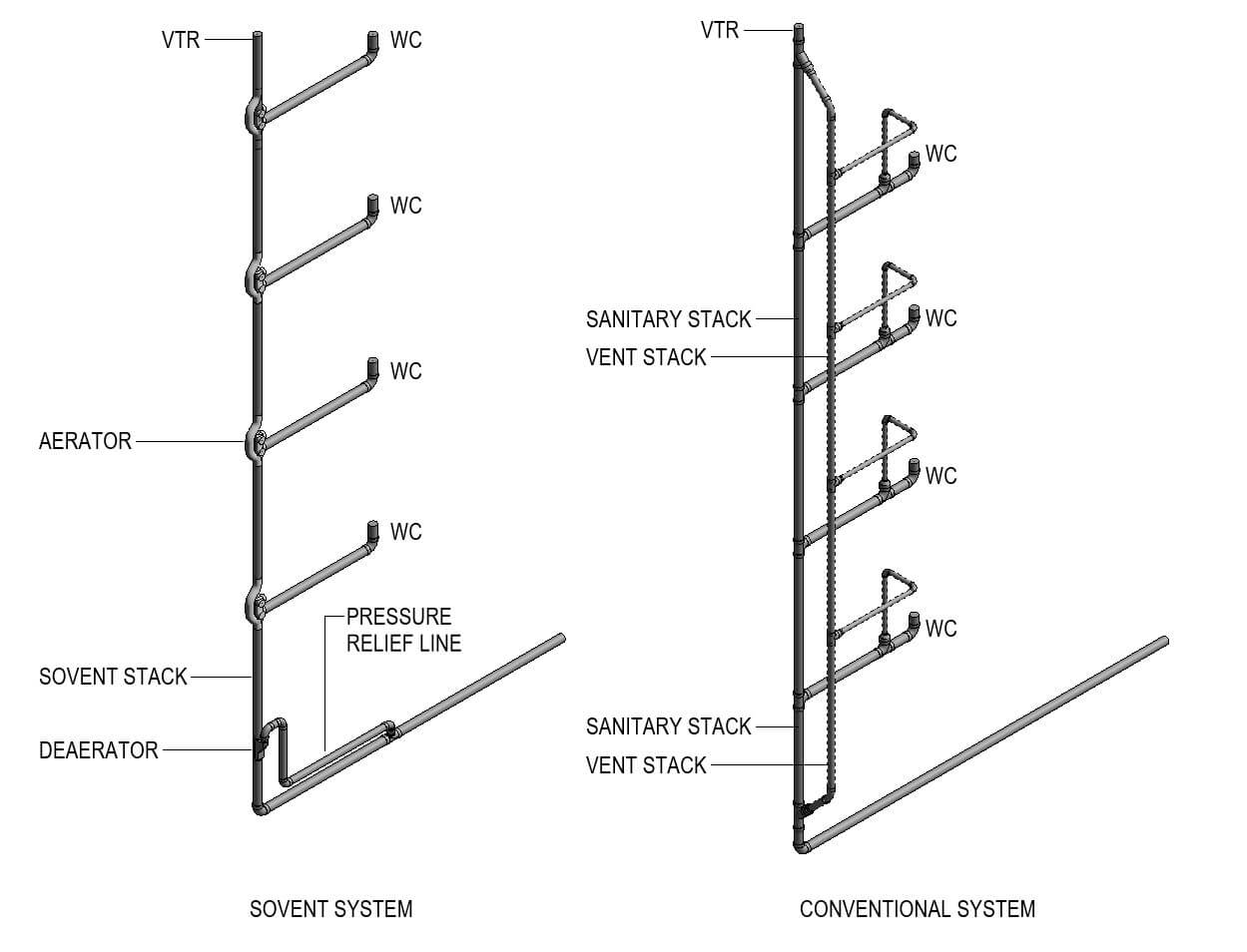

In modern building design, especially for high-rise towers, plumbing systems face increasing demands. Architects push for slimmer shafts, developers aim to cut costs, and MEP engineers must ensure reliable performance under extreme usage. The traditional waste and vent system has served us well for decades, but in tall and space-restricted buildings, it can feel outdated and inefficient. That’s where the Sovent Drainage System comes in, an engineering innovation that merges efficiency with practicality by replacing two vertical stacks with just one.

Conventional systems require:

More stacks mean:

The higher the building, the greater the variation in air pressure within stacks:

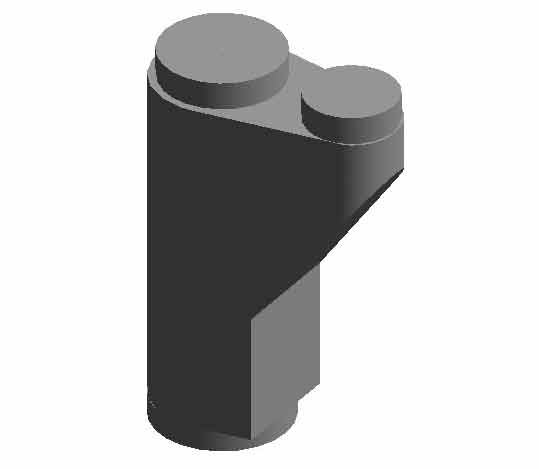

The Sovent concept replaces the traditional two-stack method with a single-stack design. Its performance is made possible by specialized fittings that control the interaction between water and air within the pipe.

Main function:

The deaerator, also known as a relief fitting, is typically installed every 10–15 floors or as determined by hydraulic calculations.

Main function:

The Sovent drainage system represents a forward-thinking solution for modern high-rise construction. By replacing the traditional dual-stack arrangement with a single, highly engineered stack, it not only optimizes space but also reduces material usage, installation time, and overall costs—while maintaining reliable hydraulic performance. Its use of aerator and deaerator fittings ensures a stable air-water balance, safeguarding trap seals and minimizing pressure fluctuations, which are critical in tall structures. Although the system requires specialized design expertise and may face regulatory limitations in certain regions, its benefits—ranging from space efficiency to sustainability—make it an attractive option for developers, architects, and engineers striving to deliver high-performance, future-ready buildings. As cities continue to grow vertically, Sovent technology is set to play a pivotal role in shaping smarter, greener, and more efficient drainage infrastructure for the next generation of high-rise developments.