Understanding Connected Load Vs Demand...

January 2, 2026

Connected Load and Demand Load are two essential terms in electrical engineering that are often misunderstood or used interchangeably. Although they appear similar, misunderstanding the difference can result in oversized electrical equipment, increased installation costs, and inefficient use of power.

Connected Load refers to the total rated electrical power of all devices, appliances, and equipment connected to an electrical system. It is calculated by adding the nameplate ratings of each load, assuming that all equipment operates simultaneously at its maximum capacity.

In practice, this condition rarely occurs, but the connected load represents the maximum possible load that could be imposed on the system.

Demand Load represents the highest level of power actually drawn by the electrical system during normal operation over a specific period. Unlike connected load, it accounts for the fact that not all electrical equipment runs at the same time or at full capacity.

Demand load provides a more realistic picture of system usage and is critical for proper sizing of transformers, generators, cables, and protective devices.

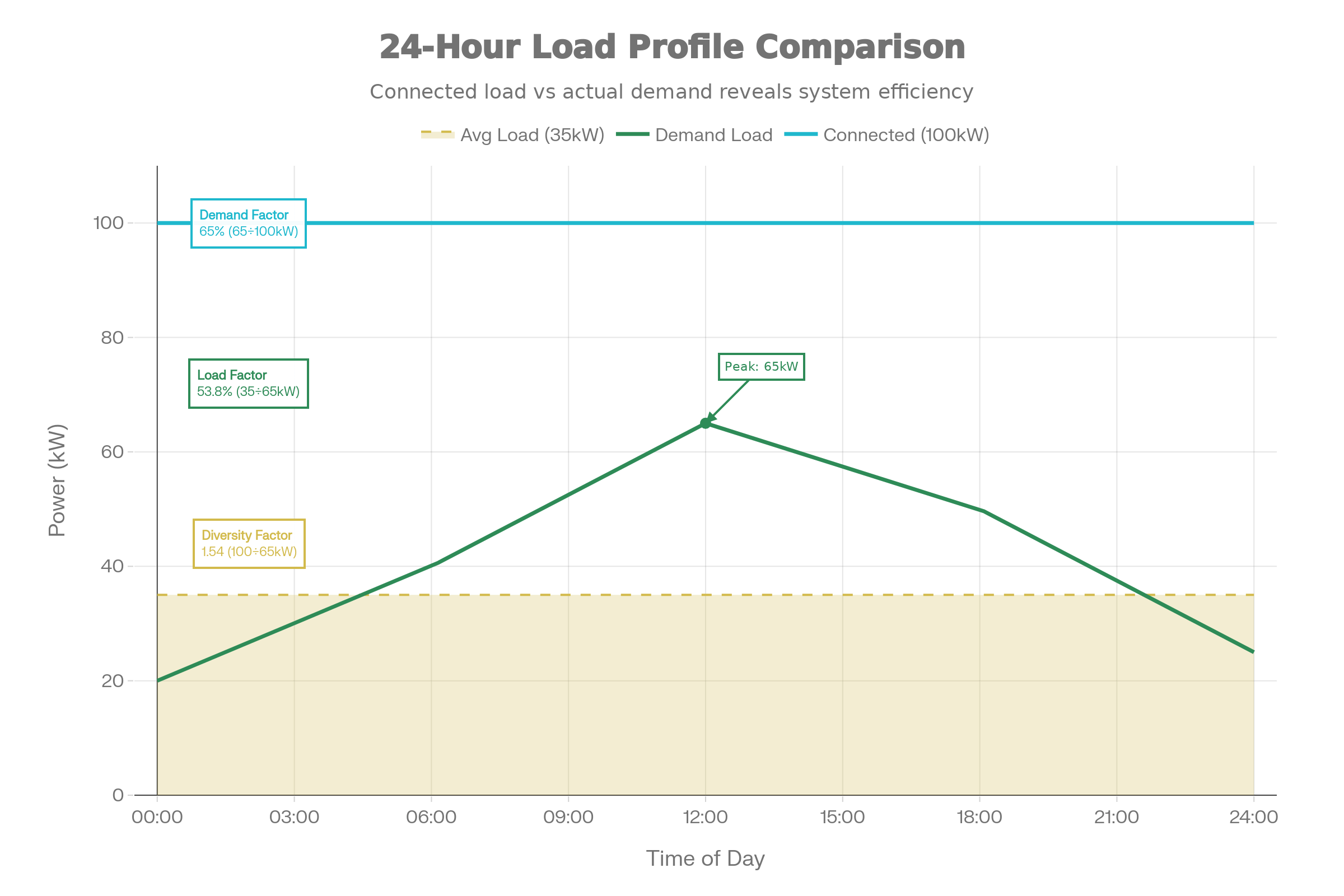

The demand factor is an important electrical parameter that indicates how much of the connected load is actually utilised at peak operation. It is defined as the ratio of the maximum demand of a system to its total connected load.

Demand Factor = Maximum Demand / Connected Load

Since all electrical equipment rarely operates at full capacity at the same time, the demand factor is always less than one. This factor helps engineers determine realistic power requirements rather than assuming worst-case conditions.

Demand factor plays a crucial role in electrical system design by preventing oversizing of transformers, generators, cables, and switchgear. It also helps utilities and facility managers plan power distribution efficiently, control peak demand, and reduce unnecessary capital and operating costs.

The diversity factor is an electrical engineering term that describes how individual loads in a system reach their maximum demand at different times. It is defined as the ratio of the sum of the individual maximum demands of various loads to the maximum demand of the entire system.

Diversity Factor = Sum of Individual Maximum Demands / Maximum Demand of the System

The value of the diversity factor is always greater than one, because it is unlikely that all connected loads will operate at their maximum simultaneously. A higher diversity factor indicates better load distribution and more efficient utilisation of electrical equipment.

Diversity factor is essential for economic and practical electrical system design, as it allows engineers to reduce the size of cables, transformers, and generators without compromising safety or reliability.

The primary purpose of a connected load is to establish the maximum potential electrical requirement of a building or facility. It provides engineers with a complete picture of all installed electrical equipment before considering operating diversity.

Utilities often require the connected load to:

Connected load is essential for:

Connected load reflects the total installed electrical capacity, helping facility owners and engineers:

The primary purpose of demand load is to determine the true electrical requirement of a facility. Electrical components such as feeders, transformers, generators, and switchgear are sized based on demand load rather than connected load to avoid unnecessary oversizing.

Designing solely on connected load results in:

Utilities often base service charges on:

Proper demand load calculation helps in:

Knowing the connected load helps engineers design electrical systems correctly by selecting suitable cables, transformers, generators, and switchgear.

It ensures the correct rating of protective devices such as fuses and circuit breakers, reducing the risk of overheating, fire hazards, and equipment damage.

Connected load provides a basis for calculating maximum demand and applying demand or diversity factors for efficient load management.

Utility companies use connected load data to plan generation, transmission, and distribution systems and to prevent overloading.

It helps estimate electricity consumption, billing, and selection of appropriate tariff categories.

Understanding the connected load allows for easy planning of system expansion and addition of new electrical equipment.

Helps identify excessive or unnecessary loads and promotes efficient utilization of electrical energy.

Demand load helps in selecting the correct capacity of transformers, generators, feeders, and switchgear, avoiding oversizing or under sizing.

Since not all equipment operates simultaneously, the demand load gives a realistic picture of actual power usage, improving system efficiency.

Electrical infrastructure and operating costs are reduced by designing systems based on demand load rather than total connected load.

Proper knowledge of demand load ensures the correct rating of protective devices, minimising the risk of overloads, overheating, and failures.

Power utilities use demand load data to plan generation schedules, distribution networks, and load-shedding strategies.

Monitoring demand load helps consumers control peak demand, reduce energy bills, and improve power factor.

Demand load analysis assists in predicting future requirements and planning system expansion.

Connected load represents the complete installed electrical capacity, whereas demand load indicates the real power requirement during operation. Knowing the difference allows engineers to design systems that are safe, cost-effective, and efficiently matched to actual usage.