Understanding Connected Load Vs Demand...

January 2, 2026

HVAC efficiency ratings are metrics used to measure the performance and energy efficiency of heating, ventilation, and air conditioning (HVAC) systems. These ratings help consumers understand how effectively an HVAC system uses energy to provide heating or cooling. Understanding these ratings can help you choose an HVAC system that will save energy and reduce utility bills. Here are some common HVAC efficiency ratings:

COP is a measure of the efficiency of heat pumps, refrigerators, and air conditioning systems. It indicates how effectively a system uses energy to provide heating or cooling. Here’s a detailed explanation:

COP is defined as the ratio of useful heating or cooling provided to the work (energy) required to achieve that heating or cooling. The formula is:

EER is a key metric used to evaluate the efficiency of air conditioners and heat pumps. It measures how efficiently a cooling system operates at a specific outdoor temperature. EER is typically measured under standardized conditions to ensure consistency. These conditions usually include:

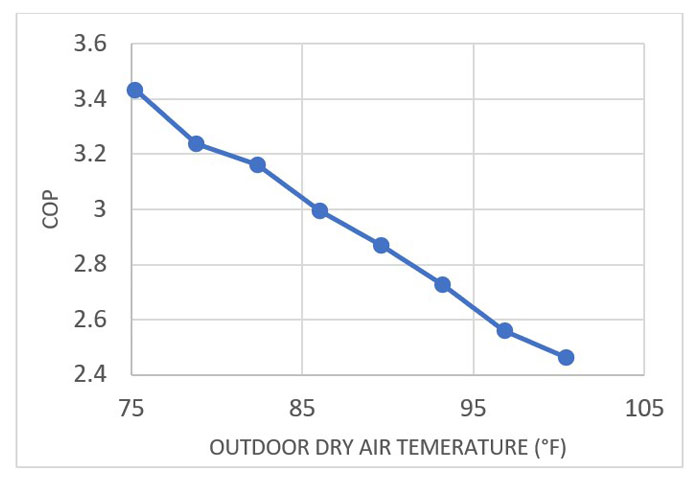

EER is calculated by dividing the cooling output (in British Thermal Unit per Hour, or BTUH) by the electrical energy input (in watts) under specific conditions. In other words, EER is 3.412 times COP at 95°F. The formula is:

EER = 3.412 × (COP @ 95°F)

Example

If an air conditioner has a cooling output of 11,340 BTUH and consumes 1,257 watts of electricity at a specific outdoor temperature (usually 95°F), its EER would be:

This means the unit provides 9.02 BTUH of cooling for every watt of electricity consumed.

The EER rating was used until the 31st of December 2022. Starting from the 1st of January 2023, the EER2 rating (Energy Efficiency Ratio 2) has been adopted as the new standard.

To illustrate, a 12 EER rated AC will not correspond to a 12 EER2 rated AC. In fact, the EER2 rating is approximately 4.1% lower than the older EER rating. For example, an AC unit previously rated at 12 EER will now be rated at 11.5 EER2.

Although the calculation method for EER2 remains the same as for EER, the difference arises from the test conditions. The EER2 rating is determined under more stringent conditions compared to the EER rating. Specifically, the main difference is due to the use of different external static pressures: 0.1 in. WC for EER and 0.5 in. WC for EER2.

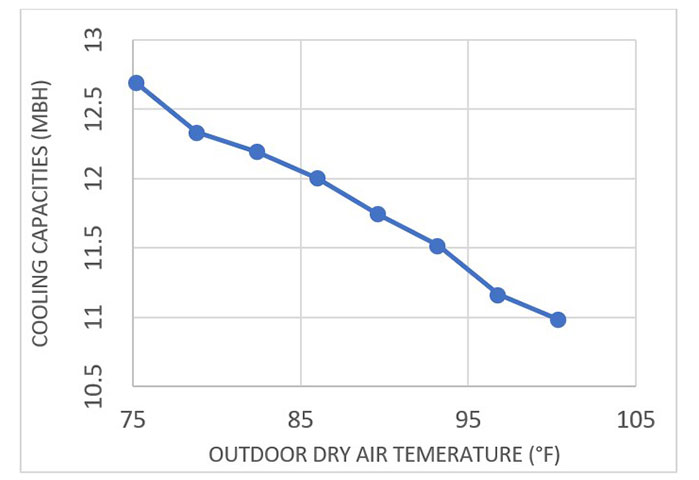

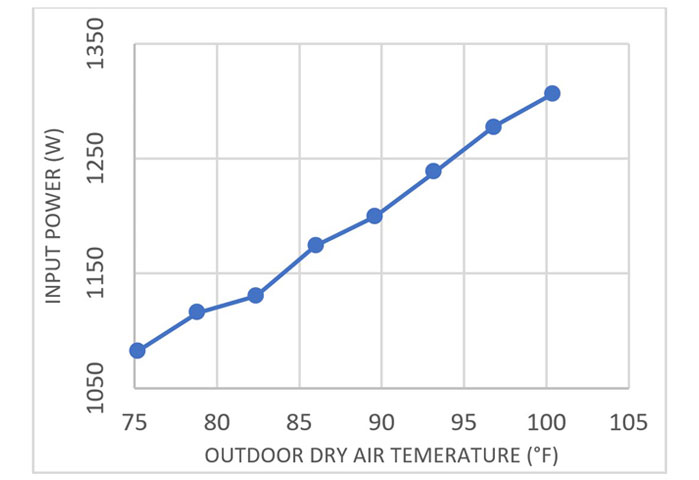

The graphs below depict how varying outdoor air temperatures affect the performance of an AC unit.

While COP and EER are valuable metrics, they have a significant limitation: they do not account for the efficiency of cooling equipment across the varying temperatures experienced during summer. To address this, the Air Conditioning, Heating, and Refrigeration Institute (AHRI) developed the Seasonal Energy Efficiency Ratio (SEER). SEER measures the average performance of air conditioners and heat pumps throughout the cooling season.

SEER is defined as the ratio of the total cooling output (in British Thermal Units, or BTUs) provided by the system during a typical cooling season to the total energy input (in watt-hours, or Wh) consumed over the same period. The SEER calculation uses a constant indoor temperature but considers a range of outdoor temperatures from 65°F (18°C) to 104°F (40°C). It assigns a specific percentage of time to each of eight temperature bins, each spanning 5°F (2.8°C). The formula is:

Mathematical relation between EER and SEER:

EER= – 0.02 × (SEER) 2 + 1.12 × SEER

The SEER rating was used until December 31, 2022. Starting January 1, 2023, the SEER2 rating (Seasonal Energy Efficiency Ratio 2) has been adopted as the new standard.

It’s clear that SEER and SEER2 are not the same, with the SEER2 rating being lower than the previous SEER rating. The key difference between SEER and SEER2 ratings lies in the test conditions:

SEER measurements are taken at 0.1 inches of water column external pressure.

SEER2 measurements are taken at 0.5 inches of water column external pressure.

Although the calculation method for SEER2 remains the same as for SEER, the difference arises from these varying test conditions.

This value better reflects the true efficiency of HVAC equipment. The Integrated Energy Efficiency Ratio (IEER) measures the energy efficiency of HVAC systems, like air conditioners and heat pumps, under different load conditions.

To determine IEER, efficiencies are recorded at various loads (with outdoor temperatures between 65°F and 95°F) and then weighted to calculate an overall efficiency score. Interestingly, peak load efficiency contributes only 2% to the total value! The IEER is calculated as follows:

IEER = (0.02 × A) + (0.617 × B) + (0.238 × C) + (0.125×D)

HSPF is a measure of the efficiency of air source heat pumps in heating mode. It indicates how effectively a heat pump converts electricity into heat over an entire heating season.

HSPF is defined as the ratio of the total heat output (measured in British Thermal Units, or BTU) provided by the heat pump during the heating season to the total electricity consumed (measured in watt-hours) over the same period. The formula is:

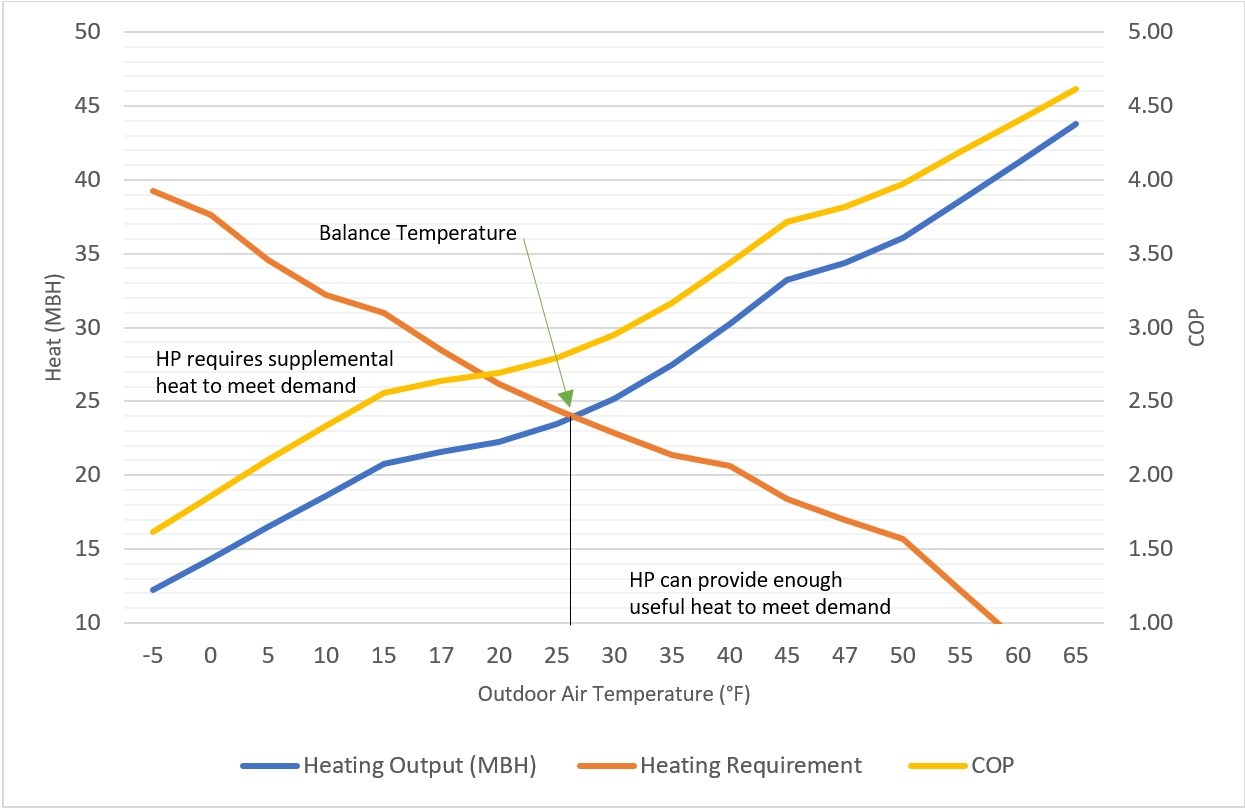

The chart below illustrates how outdoor air temperature affects the COP of a typical heat pump (HP). At the balance point, a typical HP maintains a COP of around 2.8, continuing to generate efficient heat. However, HPs encounter another performance challenge regarding supply air temperatures in colder conditions. As the outdoor temperature drops, the HP eventually becomes unable to produce supply air temperatures that are sufficiently warm for comfortable use. The Heating Seasonal Performance Factor (HSPF) is calculated by considering the COP over a wide range of temperatures.

This rating measures how effectively a furnace transforms fuel into heat throughout the year. AFUE represents the ratio of the furnace’s yearly heat output to its total annual fossil fuel energy consumption. For instance, an AFUE of 82% signifies that 82% of the fuel’s energy is converted into heat for the home, while the remaining 18% is lost as exhaust. The AFUE is established under standardized testing conditions, which encompass various operating transients and steady-state scenarios to mimic real-world usage. The AFUE is computed using the following formula: